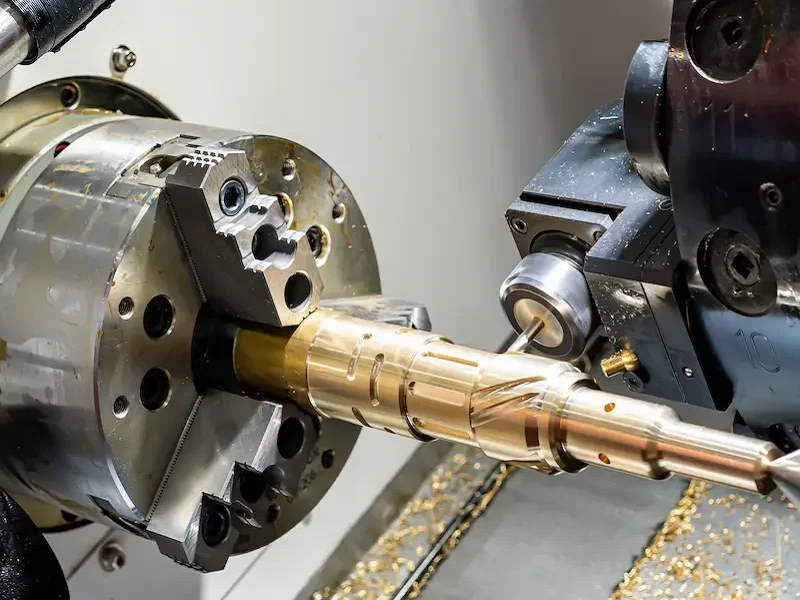

Metal CNC Machining

Metal CNC machining refers to the precise cutting, shaping, and finishing of metal parts using Computer Numerical Control (CNC) machine tools. It is widely used in industries such as automotive, aerospace, medical devices, robotics, and consumer electronics. Our factory has over 50 machines, including three-axis and five-axis machines, turning machines, drilling and tapping machines, laser cutting machines, 3D printers, and more. Our team of machining technicians primarily uses three-axis and five-axis CNC machine tools to produce all metal parts that pass our online Design for Manufacturability (DFM) check. The advanced metal CNC machine tools we use enable us to machine complex features on parts with extremely high precision while maintaining tight tolerances.

Custom CNC Machining Materials

Aluminum

Aluminum is characterized by its lightweight nature, moderate strength, and excellent corrosion resistance. It offers outstanding machinability and high thermal and electrical conductivity. A natural oxide layer forms on its surface, providing enhanced durability and environmental resistance. Aluminum is also non-magnetic and highly recyclable, making it widely used in aerospace, automotive, electronics, and architectural applications..

- model: Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380)

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances:±0.125mm (±0.005″)

- Available Finish: As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Copper

Copper is known for its exceptional electrical and thermal conductivity, making it one of the most essential materials in the electronics and power industries. It also offers excellent ductility, corrosion resistance, and natural antimicrobial properties, allowing it to perform reliably in various environments.

- model: Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Available Finish: As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish

Brass

Brass is an alloy composed primarily of copper and zinc, offering good mechanical strength and excellent machinability. It provides outstanding corrosion resistance and wear resistance, allowing it to perform reliably across various operating conditions.

- model: brass210、230、260、270、370、3770

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Available Finish:As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish

Stainless Steel

Stainless steel also provides good workability, enabling welding, forming, and precision machining,stainless steel is widely used in mechanical components, food processing equipment, medical instruments, chemical systems, and architectural applications..

- Model: Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Avaiblae Finish:As machined, Electroplating, Passivation, Powder coating.

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

- model: Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Available Finish: As machined, Polishing, Sand Blasting, Tumbling, Electropolish, Alodine, Anodizing, Electroless nickel, Painting, Powder coating, Brushed finish

Mild Steel

Mild steel has a wide range of uses due to its good machinability and low cost. Most grades can be cold-formed or hot-rolled. Mild steel is used for parts that may be surface hardened but do not have a stringent core strength.

- Model: Q195、Q215、Q235、08F、10、15

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Available Finish: Electroplating,Hot Dip Coating,Powder Coating,Painting,Nitriding,Polishing / Brushing,Blackening.

Inconel

Inconel is a precipitation-hardening alloy that exhibits high-yield stress and excellent resistance to fatigue and creep. Due to its high oxidation resistance and high strength at high temperatures, Inconel is widely used in the aerospace industry, especially as a material for producing gas turbine engine rotors.

- Model:N06600,N06601,N06617,N06625,N0669.

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Available Finish: Passivation,TiN / CrN / TiAlN,Electropolishing,HVOF / Plasma.

Alloy Steel

In order to improve the strength, toughness, hardenability, weldability, and other properties of steel. Alloy steel is divided into low alloy steel (alloy elements less than 5%); medium alloy steel (alloy elements are at 5%-10%); high alloy steel (alloy elements are greater than 10%) according to the content of alloy elements. Generally speaking, the higher the alloy content, the better the performance of the steel and the higher the price.

- Model: 4130,4140,4145,4340,8620

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Available Finish: Polishing,Brushing,Sandblasting,Black Oxide,Carburizing.

Tool Steel

Tool steels are characterized by their durability, high hardness, high wear resistance and resistance to deformation, as well as their ability to retain their cutting edges at high temperatures and withstand impact without deformation.

- Modele:1018,1020,045,4130,4140,4340,52100

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Available Finish:Polishing,Nitriding,Electroplating,Black Oxide.

Invar

Invar expansion coefficient is small, strength and hardness are not high, thermal conductivity is low, plasticity and toughness are high, which has unique advantages in making carbon fiber composite molds.

- Modele: GB/T 14953,G4805,K93601。

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Available Finish:Polishing,Nitriding,Electroplating,Black Oxide.

Our Metal CNC Machining Capabilities

3/4 Axis CNC Machining

"3/4-axis CNC machining provides high-precision, efficient manufacturing of prismatic, multi-face, and cylindrical parts. Ideal for prototyping and production in aerospace, automotive, medical devices, robotics, electronics, and industrial equipment."

CNC Turning & Mill-Turn Machining

CNC turning and mill-turn machining delivers precise, complex cylindrical and multi-feature parts in a single setup. Widely used in aerospace, automotive, medical devices, robotics, electronics, and industrial machinery for efficient prototyping and production.

5 Axis CNC Machining

5-axis CNC machining enables precise, complex 3D parts with multi-angle surfaces in a single setup. Ideal for aerospace, automotive, medical devices, robotics, electronics, and energy industries, ensuring high accuracy, superior surface finish, and efficient production.

Contact Us

Yangzheng Engineer Support Team - Real human quotes are more accurate than software quotes

Yangzheng Support team: 1@yzkjcnc.com

CNC Metal Fabrication

Metal CNC Machining Services – Precision, Reliability, and High-Quality Metal Parts Our metal CNC machining services provide high-precision manufacturing for a wide range of metals, including aluminum, stainless steel, steel alloys, titanium, copper, and brass. With advanced 3-axis, 4-axis, 5-axis, and mill-turn CNC machining, we deliver accurate, repeatable, and complex metal parts for both prototyping and production. As a professional metal CNC machining service provider, we focus on tight tolerances, superior surface finishes, and optimized machining strategies that reduce lead times and cost. From simple brackets to intricate multi-axis components, our team ensures your metal parts are produced with consistent quality and high efficiency. Metal CNC machining is widely used across aerospace, automotive, medical devices, robotics, electronics, industrial machinery, and energy industries. Whether you need lightweight aluminum parts, high-strength steel components, or precision titanium structures, we deliver durable and reliable solutions tailored to your needs. Choose our custom metal CNC machining services to turn your design into high-performance parts with speed, accuracy, and engineering support through every stage.

Why Choose Metal CNC Machining?

Exceptional Precision Metal CNC machining offers unmatched accuracy for complex geometries and tight tolerances. This ensures every part meets strict performance and assembly requirements. Superior Strength & Durability Metals such as aluminum, stainless steel, steel alloys, and titanium provide excellent mechanical strength, heat resistance, and long-term reliability—ideal for demanding applications. Versatile Manufacturing Capability From simple prismatic shapes to intricate multi-axis features, CNC machining supports diverse metal parts across small batches, prototypes, and high-volume production. Consistent Quality & Repeatability Automated machining ensures part-to-part consistency, stable performance, and reduced risk of defects, making it suitable for critical industries. Wide Industry Applications Metal CNC parts are widely used in aerospace, automotive, medical devices, robotics, electronics, and industrial equipment due to their precision and durability.

Yangzheng Precision Machining Shops provides online engineering customer support for your parts, 2D and 3D drawing design, and manufacturing questions. Assist in reviewing project plans; this includes case-by-case suggestions to help you reduce costs early on in the design process.online CNC precision machining parts, making it an excellent choice for parts prototype design and low to high-volume production runs, instant CNC parts quotes, on-time delivery, 100+ materials and 50+ surface finishes for tolerances down to 0.01mm.

CNC Machining Service Quote

People Also Ask

What is metal machining?Metal machining is a process used to shape and cut metal pieces. It involves the use of specialized tools, such as lathes and drill presses, to cut and shape the metal into the desired shape. How much does metal CNC machining cost?The cost of metal CNC machining depends on the complexity of the job and the type of metal being used. It can range from a few hundred dollars for simple jobs to thousands of dollars for complex jobs. What can you make with a metal CNC machine?A metal CNC machine can be used to make a wide range of products, including car parts, medical devices, electronics, and tools. CNC Machining of Metal Parts vs 3D PrintingCNC machining and 3D printing are both used to create parts and products. CNC machining is more precise and accurate than 3D printing, and is used to create parts with complex geometries. CNC machining is also typically used for parts with materials that cannot be 3D printed. 3D printing, on the other hand, is usually faster and more cost-effective and is used for prototyping and low-volume production. |