From CNC Prototype to Mass Production

We understand that high quality and service are essential in today's market. The continuous success of Yangzheng Machining Manufacturer can be attributed to the advanced technology and on-time delivery we provide for your prototype parts and the manufacturing specifications of mass production.

Rapid Prototyping

Our minimum order quantity is 0. Yangzheng's efficient R&D capability and advanced prototype manufacturing workshop can quickly bring your products to the market, which will help you save time to market.

On-Demand Production

Accurately manufacturing complex geometric 5 axis parts according to customer requirements without the need for large-scale production, reducing the cost of large-scale manufacturing.

Small Lot Production

It can quickly handle smaller batch production tasks, help manufacturers produce more products in a shorter time, enhance competitiveness, and increase sales..

5 Axis CNC Machining Tolerance

Feature |

Description |

|

Maximum Part Size |

400 × 300 × 200 mm 15.7 × 11.8 × 7.8 in. |

|

Standard Lead Time |

3 business days |

|

General Tolerances |

Tolerances on metals will be held to +/- 0.005" (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”. |

|

Precision Tolerances |

Yangzheng can manufacture and inspect to tight tolerances per your drawing specifications including GD&T callouts. |

|

Minimum Feature Size |

+/- 0.2mm +/- 0.007in.. |

|

Threads and Tapped Holes |

Yangzheng can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

|

Edge Condition |

Sharp edges are broken and deburred by default |

|

Surface Finish |

The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

Materials for 5 Axis CNC Machining Service

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Price: $$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances:±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

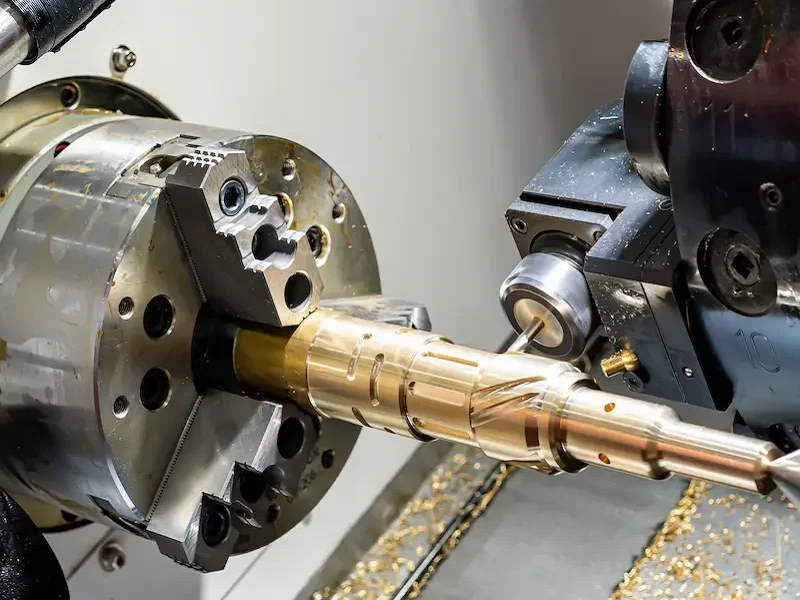

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

- Price: $$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size:200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

- Price: $$$$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Plastics

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

- POM

- Nylon

- ABS

- PEEK

- PTFE

- PC

- HDPE

- PVC

- PMMA

- PET

- PP

Surface Finishes for 5CNC Machining Parts

You can choose a wide selection of metal surface finishing services after machining at Yangzheng CNC machining manufacturer to improve the parts appearance, surface finishes, corrosion resistance, and other performance of your 5 Axis CNC Machining parts.

| Name | Description | Materials | Texture | |

|

Anodizing | The aluminum alloy is treated with hard anodic oxidation, and the surface can form a film layer with a thickness of 30-50 μm and a hardness of about 500HV, which has excellent corrosion resistance and wear resistance. | Aluminum | Smooth, matte finish |

|

Bead Blasting | Spray the powder coating on the surface of the workpiece. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece to form a powdery coating. The surface color is combined with a silky and dry feel, which combines unique aesthetics with high performance of the product. | ABS, Aluminum, Brass, Stainless Steel, Steel | Matte |

|

Powder Coating | Used on some metal workpieces by spraying or fluidized bed, the powder is electrostatically adsorbed on the surface of the workpiece, and when it is completely dry, a protective film will be formed on the surface. | Aluminum, Stainless Steel, Steel,Titanium | Gloss or semi-gloss |

|

Electroplating | The process of attaching a layer of metal film to the surface of parts by electrolysis, so as to prevent metal oxidation, improve wear resistance, conductivity, light reflection, corrosion resistance and improve appearance. The outer layer of many coins is also electroplated. | Aluminum, steel, stainless steel | Smooth, glossy finish |

|

Polishing | The whole process of electrolytic polishing is basically completed automatically, so the labor cost is very low. Environmental impact: Electrolytic polishing uses less harmful chemicals. The whole process requires a small amount of water and is easy to operate. Metal parts can achieve the effect of delaying corrosion. | Aluminum, Brass, Stainless Steel, Steel | Glossy |

|

Brushing | Make the metal surface obtain a non-mirror-like metallic luster, and at the same time, the brushed treatment can also eliminate the slight flaws on the metal surface. It is used in elevator door panels, faucets, cabinets, range hoods, sinks, etc. | ABS, Aluminum, Brass, Stainless Steel, Steel | satin |

5 Axis CNC Machining Applications Industries

Crossing numerous industries, Yangzheng Manufacturing,5-axis CNC machining is widely used in aerospace, medical, automotive, and industrial equipment manufacturing to produce complex, high-precision parts with tight tolerances, superior surface finish, and reduced setup time. 5 axis cnc machining parts.

Why Choose Us for 5 Axis CNC Machining Services

We know that high quality and service are essential in today's marketplace, and Yangzheng's continued success can be attributed to advanced technology and on-time delivery for your parts.

With manufacturing specifications for prototyping and mass production, CNC in-line turned parts will reduce the cost of your project, while we do not compromise on quality. In addition, this production does not result in other wastage as compared to traditional manufacturing. Custom CNC turned parts are a way to reduce costs across the board without taking a step back in quality.

More accurate Products

Compared with traditional production methods, the main difference and benefits of using CNC machining are: more machining processes are automated, reducing the occurrence of human errors and meeting people's higher precision needs for products.

Mass Production

CNC machine tools are suitable for various cutting methods. In the process of CNC turning,

Makes it possible to manufacture complex exterior and interior geometries. Suitable for production from 1 part to 1 million parts.

Personnel Safety

Although the operator plays an important role in CNC machining, the operator does not operate on the machine with his hands, but on the computer. This creates a safer working environment for all and reduces workplace accidents.

Fast Delivery

If you have a new product that needs to be launched as soon as possible, Yangzheng's CNC machining service can provide high-precision prototype parts within 1 day at the earliest. You just need to tell us your needs, and we will do the rest.

Customized Service

You can choose the most suitable metal and plastic from 50 materials, and 10 surface treatment services can also meet any characteristics of the product, and produce the parts you are satisfied with in the most stringent manufacturing specifications.

Reduced Energy Consumption

The natural gas and oil industries are consuming extreme energy. We are seeing the effects of constant consumption as climate and environmental change. Scalability is a huge part of the custom turned parts online, machines minimize energy losses due to robust planning and excellent management.

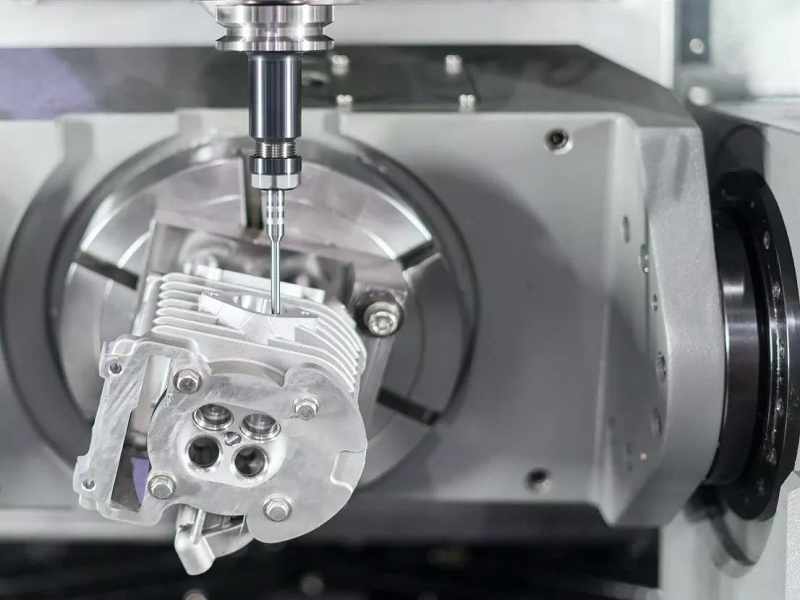

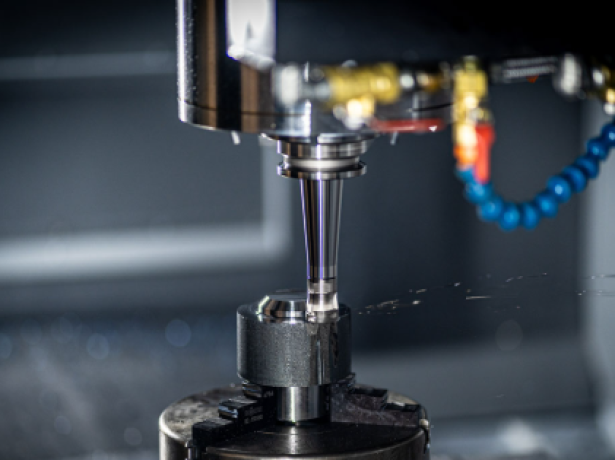

Precision cnc 5 axis parts processing diagram

Multi-variety and Low-volume production process improvement based on Yangzheng's CNC precision manufacturing shop robust design, CNC turning machining for Various Hardware Parts. The CNC 5 Axis parts meet the additional requirements of customers through anodizing and various surface-finishing and manufactured according to the requirements of drawings.

|

|

|

|

What Is 5-Axis CNC Machining?

5-axis CNC machining is an advanced manufacturing process in which a cutting tool moves along five different axes simultaneously or in a controlled sequence to produce complex and high-precision parts. Compared to traditional 3-axis machining, it allows greater flexibility, improved accuracy, and superior surface quality.5 Axis CNC machining parts.

True 5-axis machining involves the simultaneous movement of three linear axes (X, Y, Z) and two rotational axes. This enables continuous cutting at multiple angles in a single setup, making it ideal for complex geometries, freeform surfaces, and tight-tolerance components. It significantly reduces repositioning, improves dimensional accuracy, and shortens overall machining time.

2+3 axis machining (also known as positional 5-axis machining) uses two rotational axes to position the workpiece at a fixed angle, after which machining is performed using three linear axes. Although the axes do not move simultaneously, this method allows access to multiple sides of a part with fewer setups, improving efficiency and accuracy compared to traditional 3-axis machining.

Advantages of 5 Axis CNC Machining:

Yangzheng(cnc-yz.com) is capable to provide cost-effective 5 CNC cnc-machining services and quality products with high precision and accuracy for vast projects.

- Complex Geometries: Allows for the machining of intricate designs and complex shapes from any angle, reducing the need for multiple setups.

- Enhanced Accuracy: Minimizes handling errors associated with multiple setups, improving the overall accuracy of the finished product.

- Improved Surface Finish: The tool can maintain an optimal angle relative to the surface, enhancing the quality of the surface finish and reducing the need for secondary finishing operations.

- Use of Shorter Cutting Tools: Enables closer positioning of the tool to the workpiece, which reduces tool deflection and vibration, leading to more precise cuts.

- Increased Productivity: Reduces overall production time by combining what traditionally requires several machine setups into a single setup.

- Material Conservation: Efficient tool paths and advanced control minimize material waste, which is especially beneficial when working with expensive materials.

Quality control plan that reassures customers

- ISO9001 certified precision machining shop

- Performance tracking on lead time and quality

- Strict NDA agreements with Buyers

- Inspection report included in every order.

- Full dimensional inspection reports on request

- Material certifications and test reports available on request

- Batch inspection in concurrence with ISO2859

- Low Cost On Demand Manufacturing, On-Time Delivery